We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

RECOMBINANT PROTEIN

RECOMBINANT PROTEIN

Covalab provides a large and various bio production offer for proteins (tag, ...). We are using eucaryotic or prokariotic systems and offering a large range of bioproduction scale starting from mililiter and up to 12 L bioreactor. All proteins production occurs in our ISO-certified manufacturing facility.

Reactivity, high quality production and tailor made services is our main objective. Thanks to nearly 30 years of experience and our highly trained scientific team we can adapt our process to answer all your specific needs and meet your goal.

|

Eukaryote (CHO, HEK) |

Prokaryote (E. coli)

|

Transient & stable transfection |

Large scale application (from mg to g) |

|

|

|

|

Quality control |

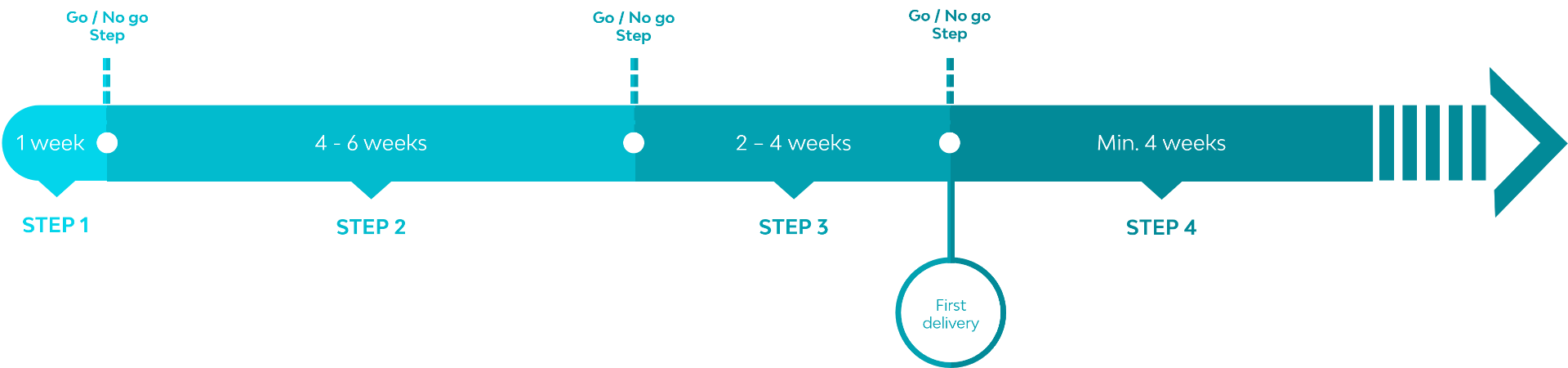

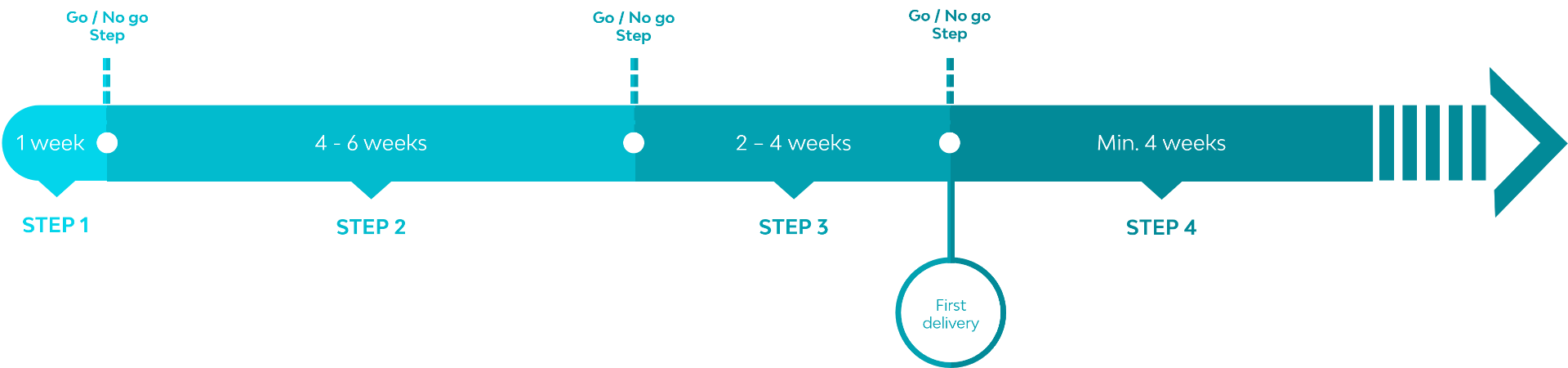

Eukaryotic production (CHO, HEK)

Eukaryotic production (CHO, HEK)

- Bibliography study

- Sequence analysis

- Expression and purification strategy proposal (tag selection)

- GO / NO GO step

- Primers design

- Gene synthesis including a tag (codon optimization)

- Subcloning into an expression vector for eukaryotic model

- Amplification and purification of the plasmid

- Control by sequencing

- GO / NO GO step

- Transient transfection in CHO / HEK cells

- Pilot production small scale volume (≈ 100 mL)

- Protein purification by affinity chromatography

- Protein characterization (SDS-Page, ELISA, flow cytometry, HPSEC, WB...) and yield estimation

- Material transfert for validation

- GO / NO GO step

- Transient transfection / Stable transfection in CHO / HEK cells

- In vitro production (1 - 12 L)

- Protein purification by affinity chromatography

- Polishing step (SEC, ion exchange...)

- Protein characterization (SDS-Page, ELISA, flow cytometry, HPSEC, WB...) and yield estimation (BCA...)

- Endotoxin level, HCPs

- Production, purification and quality control report

Total project duration: From 11 weeks (≈ 3 months)

Prokaryotic production (E. coli)

Prokaryotic production (E. coli)

- Bibliography study

- Sequence analysis

- Expression and purification strategy proposal (tag selection...)

- GO / NO GO step

- Primers design

- Gene synthesis including a tag (codon optimization)

- Subcloning into an expression vector for prokaryotic model

- Amplification and purification of the plasmid

- Control by sequencing

- GO / NO GO step

- Bacterial culture (E. coli) in tubes of 3 mL and best conditions selection

- Pilot production small scale volume (≈ 200 mL)

- Protein purification by affinity chromatography

- Protein characterization (SDS-Page, ELISA, flow cytometry, HPSEC, WB...) and yield estimation

- Material transfert for validation

- GO / NO GO step

- Production of 10 mg (for a yield of 0.5 mg /L, up to 5 L)

- Purification by affinity chromatography (in the case of tag)

- Protein purification by affinity chromatography

- Protein characterization (SDS-Page, ELISA, flow cytometry, HPSEC, WB...) and yield estimation (BCA...)

- Production, purification and quality control report

Total project duration: From 11 weeks (≈ 3 months)

Additional services

Additional services

Validation & Quality control

Validation and QC and get more information.

Purification

Purification and get more information.

Labelling

Labelling and get more information.

Brochures

Brochures

Bioproduction

Discover our complete bioproduction service.